|

|

|||||||

| The Honda CA95 / Benly 150 Restoration The little brother to the CA160 in our family of Hondas |

|

| Thread Tools |

|

#1

|

||||

|

||||

|

One thing I've enjoyed about this forum is to read about how the members have improvised tools and techniques to "get the job done". I know that I've borrowed quite a bit from this group in the year that I've been a member.

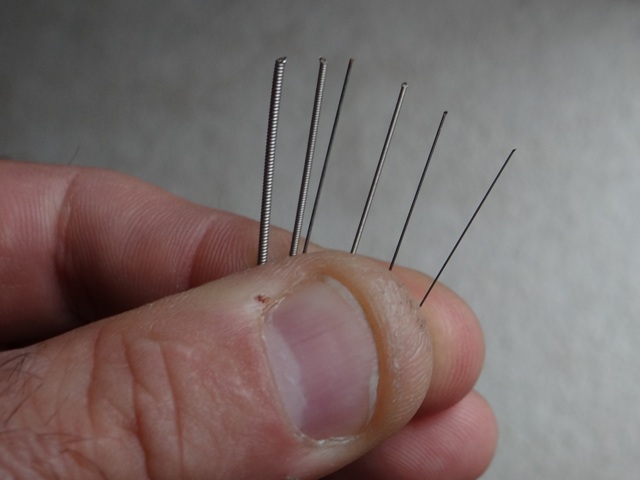

I thought I'd share one "tool" that I use during my projects. As crazy as this sounds, I save my used electric guitar strings, using them whenever I need to probe or clean tiny little passageways. I've found the larger strings to be excellent for pushing through the engine case oil galleys to ensure that no crud remains and that the oil can flow unimpeded. The tiny strings are excellent for dislodging a blockage in the tiniest of carburetor passages, and a little oil helps ensure that there's minimal scraping or damage. Best of all, a set of electric guitar strings are only $3 to $5. I use the "ball" end of the strings to attach them to a key ring, but also have longer scrap pieces for when I have deeper probing to do. I've used these strings to dislodge crud from the smallest of carburetor airways when solvent, ultrasonic cleaners and compressed air did not succeed. What are your favorite "improvised" tools in your kit?

|

|

#2

|

||||

|

||||

|

For me its probably my valve spring compressor- need to upgrade tho from PVC to metal.

sorry no pics |

|

#3

|

|||

|

|||

|

Here is my valve spring compressor. It works great with my machined 3/8" extension and drill press.

The guitar string cleaner idea is brilliant. |

|

#4

|

||||

|

||||

|

interesting idea. I have 2 small motorcycle valve compressors, but neither fits the CA95. I improvised with a 13mm box end wrench, but it was a wrestling match. I can see how your modified socket and extension on a drill press would be much easier. Thanks.

|

|

#5

|

|||

|

|||

|

Great Idea ! Now if you play bass you have throttle and clutch cables also .

|

|

#6

|

||||

|

||||

|

The VJMC website has a PDF on how to manufacture your own valve spring compressor if you don't have drill press. C Clamps are cheap at HF so I have dedicated one that worked well on both my single cyl and twins.

|

|

#7

|

||||

|

||||

|

Cool. Given how inexpensive a C-clamp is, I could probably just weld the pipe section to the clamp itself.

It's interesting to see how many people have improvised valve spring compressors. |

|

#8

|

||||

|

||||

|

Actually just weld the receiver for the "pipe" to the clamp. I find being able to position the opening on the pipe to your best position is useful. Total cost less than $10.00.

|

|

#9

|

|||

|

|||

|

I think the rear wheel spindle/axle used to pull the rotor is my top tool

|

|

#10

|

||||

|

||||

|

Tell us about that one Sam...

|

|

#11

|

|||

|

|||

|

Screw the rear axle into the rotor, put a bar through the hole and give it a sharp tap with a hammer and it will jump off, no need for a special puller.

Easy peasy. Sam.

|

|

#12

|

||||

|

||||

|

Quote:

Sam, that's too cool.

|

|

#13

|

|||

|

|||

|

No picture handy, but...

For my recent el-cheapo project (a 1976 Motobecane Moped), I needed a flywheel clamp. I ended attaching two #72 hose clamps onto the flywheel and butting their screws up against a 2x4 custom cut for the job. It's since been sharpie'd "Moby FW Block" and made its way into my moped repair spares. Other than that... I picked up a used ultrasonic cleaner (Staedler-mars) for cleaning drafting pens, with a tank just large enough to do the bottom half + galleries of a 24mm carb. Individual parts can also be cleaned in more hazardous solvent by placing the solvent (flammable or not) inside a sealed jar, and filling the balance of the chamber with water. I learned that trick while learning from a watchmaker. Oh, and a big ditto on the guitar strings - a great help on a recent carburetor cleaning. |

|

| Thread Tools | |

|

|