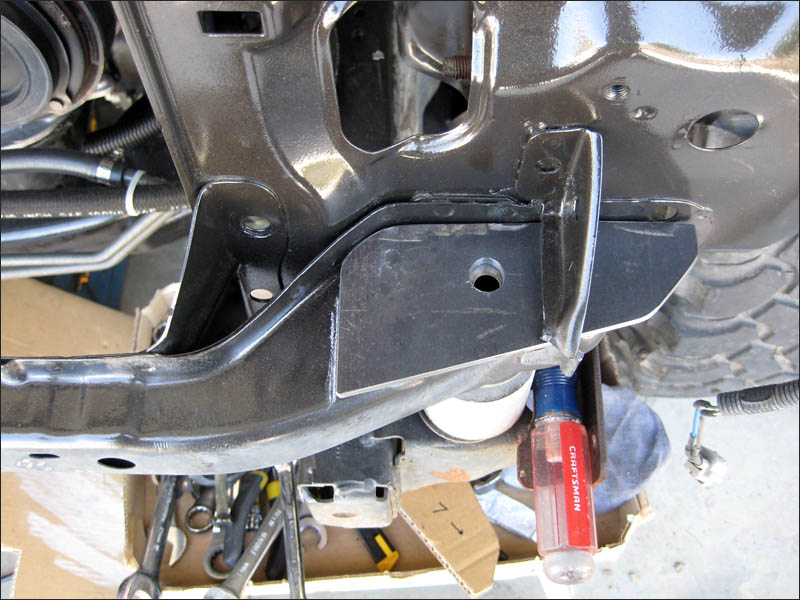

Here is the upper plate I cut and drilled. The tubing will weld right on to it and go from side to side. I'll be making a larger plate that will mount underneath the one that you see here and it will sandwhich the crossmember end as that part is body welded and glued to the body pretty good. Then I will box that piece in with steel to enclose the crossmember end. I'll also be welding the upper and lower plate to the body as well for good measure. Then right where you see the chalk line is right where I'm cutting the stock crossmember out and then I'll keep cutting up into the body to remove more and more flimsy stock material. Then the rest is a little hard to explain but that's a good enough start for now. I have it all in my head and it will go really fast once I'm set up in the shop and turn off my phone. =]

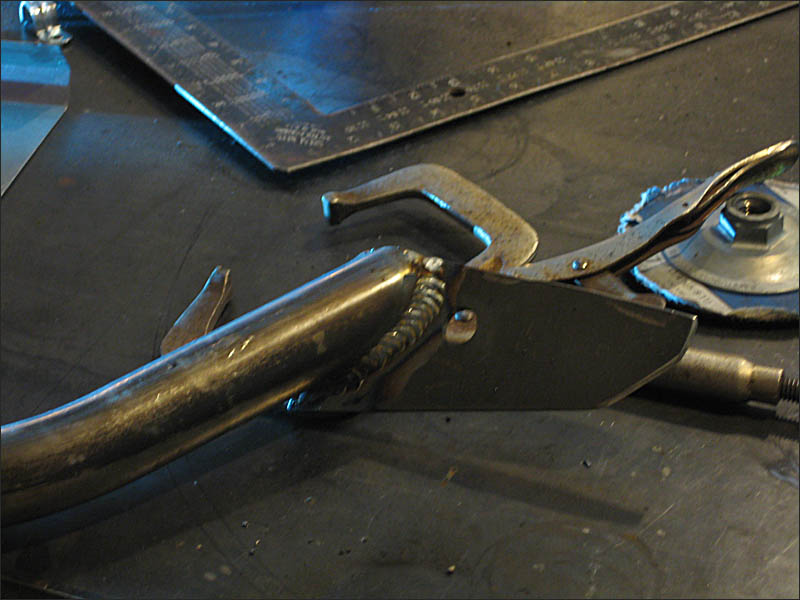

And as an update here is the assembly welded up and just strong as hell!

And as an update here is the assembly welded up and just strong as hell! There will be much more going on underneath this mounting point that I just made. There will be a bottom plate that will mount to the new frame mounts I'm making for the body. And from that lower plate to this upper plate I'll box them in and weld the body to them in a few places eventually.