Once the die is inserted I highly recommend oiling the tip of the press or the indent on the top of the die. This indent will see a lot of force from the press tip and some lube will allow things to spin easier. While you are at it make SURE to oil the threads of the press mechanism. Just like you oil the threads of any pullers for pulleys. This allows much easier operation of the tool since you will have to apply a LOT of force to make it work thoroughly.

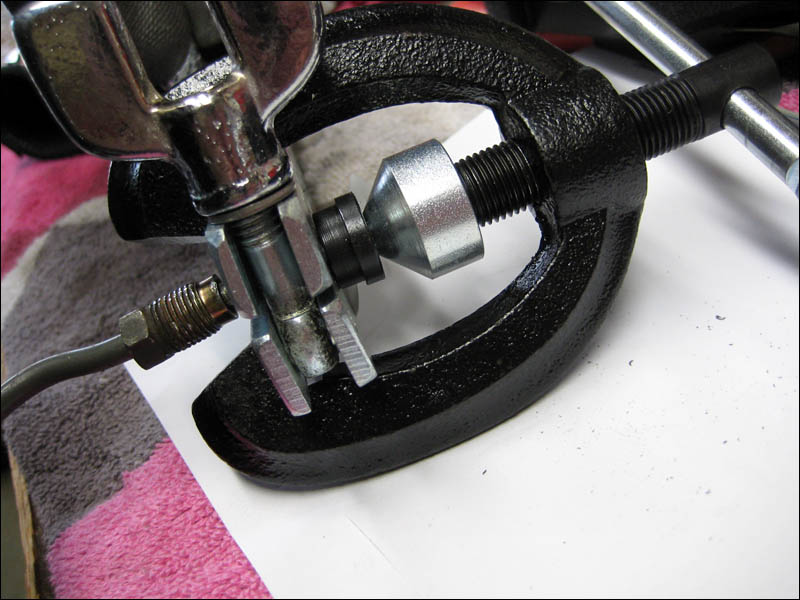

Here you can see the press after I have spun it down completely so that it meets with the surface of the clamp. This is not so easy but if you put the clamps in a vice then it's much easier to concentrate your force on the tool.