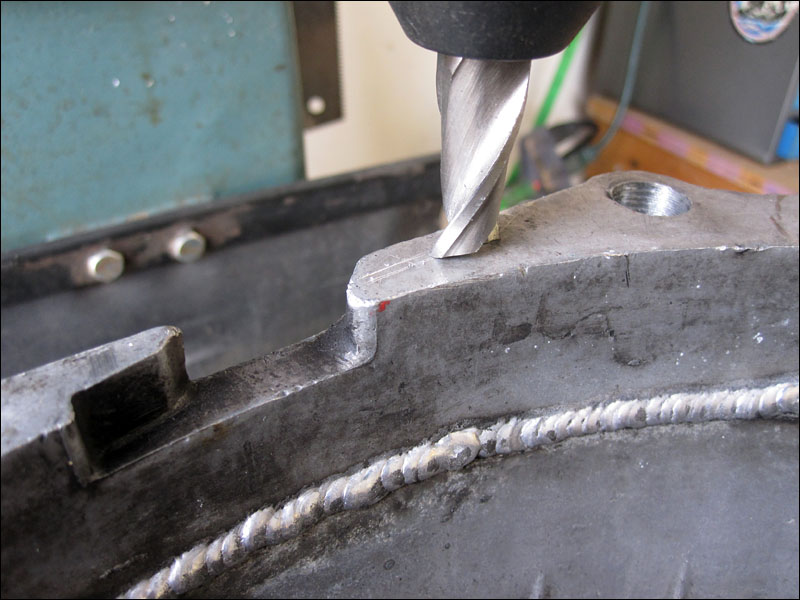

Placing the bell housing on the mill table I simply adjusted the head down just enough to skim the surface of the housing as I turned the housing using the endmill as a gauge for any changes in surface height. I used a new 2 flute endmill so that I could "draw" 2 lines while dragging it across the surface as I rotated the bellhousing (

BH from now one if you please). Of course the endmill would only etch lines in the surface if the surface rose up from the lowspot that I gauged around the edge of the BH. The surface never rose up more than enough to make a scratch in the surface as in the picture so it really wasn't as bad as I had imagined. But still enough to be of concern as tiny adjustments at this point make a big difference.

This is some pretty crazy stuff and it all takes an extremely long time and a lot of knowledge to get this stuff exact. This is the reason I recommend that people wanting this type of power just buy a Toyota Tundra as they can be found for a really good price with a factory V8 that runs perfectly and will run perfectly for years. If Tundras weren't so expensive when I first started building my custom suspension for this truck I would have started with one of those from the beginning. But back then they were expensive so I began building my truck and since I'm never getting rid of it I went ahead with this new engine. If you are considering trying to make an adapter like this I highly recommend you do not.

This takes an insane amount of time and effort.